ID # 14572938

2020 Yamaha YZF-R1

Call for Price

Overview

Specifications

Videos

|

CONQUER ROAD

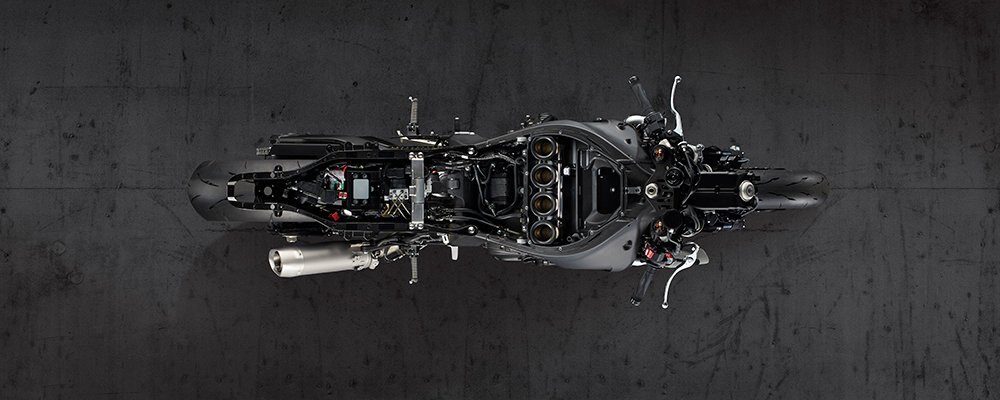

Yamaha has a rich heritage of building the most sought-after supersport motorcycles designed to deliver the pinnacle of performance on and off the track. The 2020 Yamaha R1 is forged from the technology and development gained from countless racetrack challenges, from MotoGP to the Canadian Superbike Championship. From crossplane crankshaft engines to revolutionary electronics such as the six-axis Inertial Measurement Unit (IMU), Yamaha's historical achievements have become the future of R World. |

|

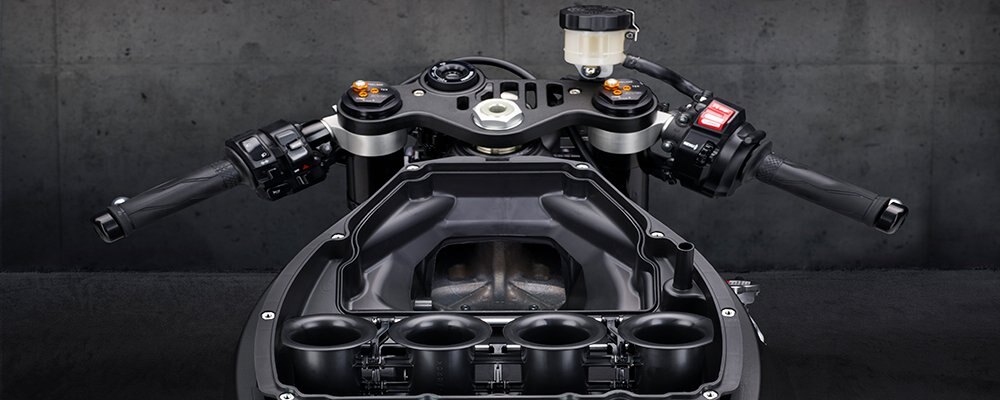

REFINED CP4 ENGINE

The new 2020 R1 comes equipped with the next generation of Yamaha's unique 998 cc inline four-cylinder crossplane crankshaft (CP4) engine for refined performance. Returning features such as titanium fracture-split connecting rods and offset cylinders contribute to a responsive and potent character, while the cylinder head, fuel injectors, finger-follower rocker arms, and camshaft profiles are new for 2020. |

|

RACING PEDIGREE

Based on 22 years of proven race-winning engineering, the 2020 Yamaha R1M and R1 are forged from the technology and development gained from countless challenges in MotoGP, World Superbike, and MotoAmerica Superbike races, and the grueling demands of Endurance World Championship racing. |

|

MULTIFUNCTION TFT SCREEN

The R1 features a brilliant full-colour, thin-film transistor (TFT) instrument screen, with front brake pressure and fore/aft G-force readouts, giving the rider even more feedback from the machine. Choose either the street or track display mode, the latter of which focuses on performance information such as YRC settings (including new Engine Braking Management and Brake Control systems), a zoomed-in view of the tachometer in the upper rpm range, a lap timer, gear position indicator and speed.

|

|

NEW FOR 2020 |

|

|

ENGINE |

|

|

|

|

ELECTRONIC RIDER AIDS... YRC | |

| |

|

CHASSIS/SUSPENSION | |

| |

|

DETAILS | |

| |

|

OPTIONAL EQUIPMENT | |

|

CCU or Communication Control Unit is a plug & play data logger with GPS based information. It is an option on the above R1 and standard equipment on the YZF-R1M premium model. Please see the R1M info for more details on the CUU and its functions. NOTE: The YZF-R1 offers a significant level of power and performance. It is not intended for novice or inexperienced riders. All information is subject to change without notice. |

Model

YZF-R1

Category Name

Motorcycles

Year

2020

Sale Type

New

Manufacturer

Yamaha

Color

Blue , Black

Engine Size

998 cc

Displacement

998 cc

Transmission

6-speed

Length

2,055 mm (80.9'')

Width

690 mm (27.2'')

Height

1,150 mm (45.3'')

Engine

Liquid-cooled, DOHC, 16-valves (4-valves / cyl), in-line four

Bore And Stroke

79 x 50.9mm

Compression Ratio

13: 1

Ignition / Starting

TCI / Electric

Final Drive

520 series ''O'' ring chain

Wheelbase

1,405mm (55.3'')

Ground Clearance

130 mm (5.1'')

Fuel Capacity

17 litres (3.7 Imp. gal.)

Model

YZF-R1

Category Name

Motorcycles

Year

2020

Sale Type

New

Manufacturer

Yamaha

Quantity

0

Color

Blue , Black

Engine Size

998 cc

Displacement

998 cc